How To Check Nut Slot Depth

- How To Check Nut Slot Depth Charts

- How To Check Nut Slot Depth Chart

- How To Check Nut Slot Depth Tool

- How To Check Nut Slot Depth Machine

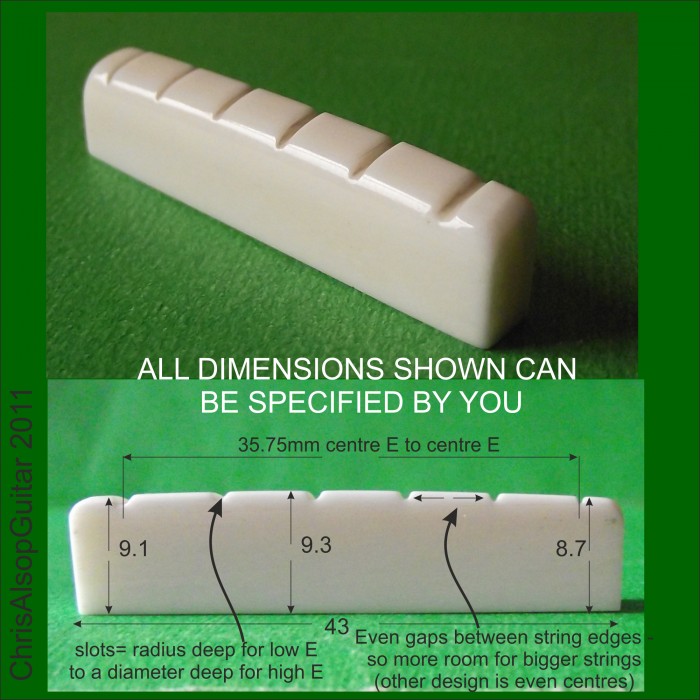

The slots on the nut are to maintain the string spacing. The best tool to use to make the slots, is a round tapering needle file. The slots only need to be half the strings thickness deep, to keep the string in place. Ideally the string will sit at the bottom of a semi circular slot, that is just a bit wider than the string. Another method of making sure you don’t run the slots two deep is stacking filler gauges next to the fret to the desired height. Then slip them to the nut and hold them back with an elastic band to keep them in place and also match the fretboard radius. If you have the ‘Safe Slot Nut Guard’ this is the place to use it. In this video, Chris May the master luthier of Overwater basses is going to show you exactly how to set the correct nut heights on your bass for optimum playability. As always, see you in the shed, Scott:) PS. This video is a snippet from our 'Bass Maintenance and Set-Up Guide' course within the SBL Academy. The course is over 2 hours long. Rather than being concerned about the apparent depth of the string in the fret slot, check the nut action to make sure the depth isn't a problem. Hold down the string behind the second fret and press down on it between the second fret and nut.

Written byGreigg Fraser Everything you need to know about your guitar nutThe nut is one of the most important exponents in the overall performance ofany guitar ... electric or acoustic. A badly worn or poorly made nut can easilyruin the tone and playability of any instrument. Nuts are made from a variety of materials including; plastic, bone, brassand graphite. Bone is perhaps the first choice of many guitarists and guitartechs alike, mainly because of the tone ... many feel that bone nuts simplysound better. For electric guitars with a vibrato system my personal choice isgraphite, or some other low friction material. (Using the vibrato bardramatically increases the chance of the guitar strings 'snagging' atthe nut). The main reason for nut replacement is simply when the old nut is too badlyworn, with the string slots carved so deep that the strings tend to 'fretout' at the first fret. This can sometimes be corrected by placing a shim(a small piece of material about the thickness of a business card) under theold nut. But if the wear is too severe...a new nut is the answer. A great way to check nut slot depth (and possible wear) is to press anystring down at the 3rd fret. There should be enough clearance between thestring and the 1st fret to slide in a piece of paper. If the string is touchingthe fret then a new nut may be in your future! Making a nut from scratch is a tall order requiring an experienced guitartech and about an hour or so of their time. The job also calls for severalspecial tools such as precision nut files, razor saw, small wood chisels, etc.But for those of you who want to learn how to do it yourself there are avariety of 'how - to' books that can help you out. A great one is the'Guitar Player Repair Guide' by Dan Erlewine. As well as a detailedstep by step explanation, there's a list of the tools you'll need and how toget them. Another alternative is to see if your guitar is a candidate for a'pre-fab' nut. These are nuts that are manufactured with the widthand height predetermined and the individual nut slots 'roughed in'.They're usually made of plastic and as long as the width and slot spacingfit your guitar it should require minimal effort to install. But for my money, having a nut made from scratch by a trusted andexperienced guitar tech using quality material is well worth it! Greigg Fraser is aguitarist/songwriter from London, Ontario, Canada. Click below to visit his web site andlisten to audio samples from his two CD's! Cleverjoe's Home Page

Guitar Strings - How to string a guitar. - Cleverjoe's Musician ResourceCentre |

After adjusting the truss rod and setting the string saddle heights at the bridge, you can now make the third adjustment, which is to the nut slots. There are three aspects of the nut slots that you will be addressing in the setup process in order to make sure that they are cut correctly:

- The nut slot depths,

- The slot widths, and

- The slot angles.

When to adjust the nut slots

You typically make adjustments to the nut after setting the bridge, as the heights of the nut slots are a function of the overall string angle. The string angle is determined by the string action height at the bridge. The individual slot depths are cut so each string can clear the first fret.

You might notice that some guitars fresh off of the showroom floor are a little difficult to play in the first position (at the first five frets). This is because the manufacturer will cut the nut slots on the high side on purpose. Then a local guitar tech at the store can adjust them to customer taste. It is much easier to cut a nut slot down than to raise it by either filling the slots or shimming the entire nut up.

The effect of nut slots that are too high

How To Check Nut Slot Depth Charts

Nut slots that are too high create a situation where the guitar is difficult to play in first position. They can also throw off the tuning and intonation. Nut slots that are too low will create what many players refer to as a “sitar” effect. This is where the string isn’t able to clear the first fret and rattles against it, creating a string buzz similar to a sitar.

The ideal nut slot height, in terms of playability, is subjective — much like string action height at the bridge. Some players like the slots to be cut up a little higher (like slide players), and some players want them cut down as low as possible so the guitar plays very easy with no fight.

You can measure the nut slot heights by placing a feeler gauge in between the bottom of the string and the top of the first fret when the guitar is up to pitch and after the neck and bridge are adjusted. This is why you use a capo at the first fret in all previous steps — to take the nut slot heights out of the equation, saving them for last.

Measuring the nut slot heights

You can start this process by making sure the guitar is up to pitch. Then read the nut slot depths. As a starting point, shoot for .02” in between the top of the first fret and the bottom of the string at the first fret on the wound strings (low E, A and D), and .018” for the plain strings (high G, B, and E). On acoustic guitars with a wound G, you will also shoot for .018” of space since this a thinner-wound string. The feeler gauge should be placed on top of the first fret, sliding underneath each string.

If there is extra space, then the slot is cut too high and will need to come down until the string lightly touches the top of the gauge. If the gauge pushes the string up, then the slot will need to be filled and re-cut to raise the slot.

Raising the nut slots

You can fill and re-cut a nut slot by wicking either bone dust or the rolled-up fibers of a Q-tip in the slot with thin Cyanoacrylate glue. Using a super glue accelerator to instantly toughen the material, trim the excess, and then re-cut the slot.

How To Check Nut Slot Depth Chart

Widening the nut slots

The individual slot widths will be a function of the individual string gauges and will determine what gauged file you use on each nut slot. As a rule, you typically want to cut a nut slot slightly wider than the actual string so the slot does not bind or choke the strings at the nut. This can cause tuning issues.

How To Check Nut Slot Depth Tool

Sometimes I will get a guitar in the shop to repair or replace tuners because the string is making a “clicking” sound when tuning. The customer assumes that the tuners are not working properly. However, most of the time the slots were binding the strings and hanging them up at the nut. I can fix the issue by simply widening the nut slots .002” over the size of the actual string width and cutting the slots correctly.

If, for instance, you are changing your string gauges from 10’s to 11’s, you will also want to widen the slots to accommodate the thicker string gauges. Again, these nut slot height measurements are workable specs to shoot for. But the customer will ultimately decide what feels right, as they can dramatically affect the playability of the setup.

How To Check Nut Slot Depth Machine

Cutting at the proper angle

The last aspect of nut slot adjustment is the angle at which it’s cut. This is determined by the string pull of the headstock (either straight string pull or angled). Whenever you are cutting a nut slot, you will always direct the file in the slot to the corresponding tuning key.

On a Gibson, (which has symmetrical offset tuners) you will direct the file with a slight angle pointing to each tuner post. Gibson and Martin guitars have a tilt-back headstock design, so you will want to angle each nut slot cut with a slight downward angle that matches the headstock pitch, leaving the highest point of the slot at the front of the nut.

On Fender guitars with straight string pull, you’ll cut straight and in-line with the tuners. On Fender guitars with a scooped headstock design, you will want almost no angle in your cuts because there is almost no break angle in the string after it leaves the nut slot on the way to its corresponding post. If you cut a nut slot on a Fender guitar with an angle, you might create a string buzz on the open notes. You can almost always fix this issue by filling the nut slots and then re-cutting them correctly.